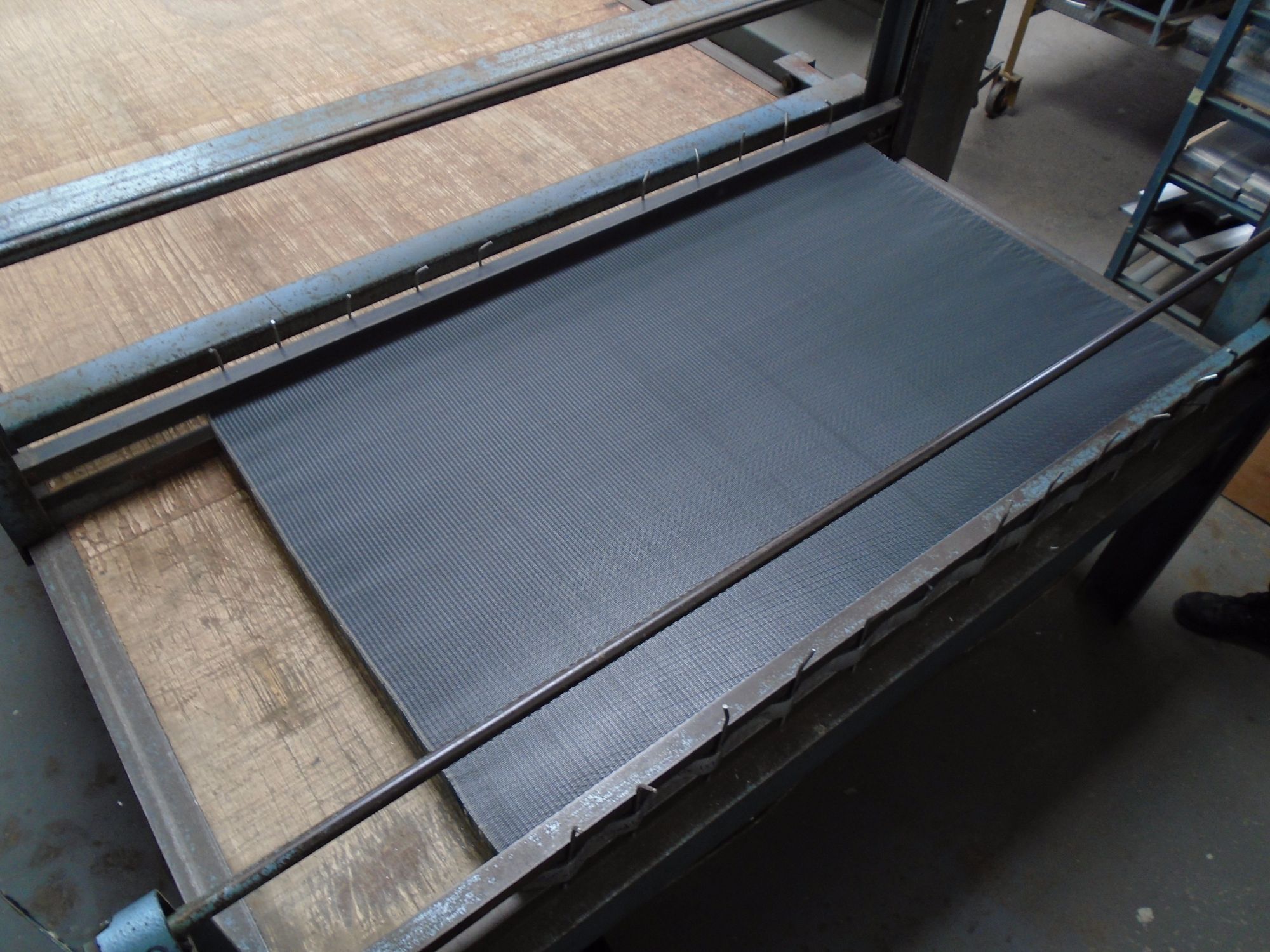

Multi-daylight Heated Hydraulic Panel Press

Bonded Components owns and operates two multi-daylight heated hydraulic presses. Our main press is a 5 platen 4 daylight press, capable of curing panels up to 180 degrees.

Press Dimensions

The press has a maximum size of 3150mm by 1350mm however the most economical size is 2500mm by 1250mm (8’ by 4’). In commercial applications and depending on its application, we are able to extend beyond this size, for further information please contact us.

Panel Pressure

The press is hydraulically operated and can pressurise the hydraulic rams up to 6000 PSI, based on a panel size of 8 by 4 foot, this equates to approximately 100 PSI.

Cold Curing

Unlike a lot of hydraulic presses, the hydraulic rams have a long stroke, allowing the press to be closed fully will minimal material. This gives us an advantage when curing cold cured panels, as we can press the panels straight away whilst subsequent panels are laminated.

3 Axis CNC large format router

Our CNC 3 Axis router is capable of machining precise and repeatable parts of up to the size of 2565mm by 1350mm by 100mm.

We are highly experienced and are capable of machining parts from either from a technical drawings or directly from CAD data such as 2 Dimensional (*.DXF or *.DWG) files or 3 Dimension models (*.IGS).

If you have a different format not listed above, please contact us for further information about the files we can work to.

Core Expansion Table

Prior to laminating, the core slices are expanded from their HOBE (HOneycomb Before Expansion) state to the honeycomb lattice structure, maintaining the correct cell size. This process can be done either by hand or using a core expansion table.

Bonded Components operate a motorised expansion table, allowing for an even and consistent expansion of the honeycomb.